Tips on Pouring Epoxy Resin

Regardless of whether it's your first time assembling an epoxy resin blend or if you’re a seasoned pro, you should always keep in mind these tips and tricks for getting the best mix for your project. Before proceeding with the topic, let’s first learn more about epoxy resin.

How Does Epoxy Resin Work?

Epoxy resin comes in two sections: the resin and the hardener. When the resin and hardener are combined, a synthetic response happens that cause heat production. This heat changes the epoxy from fluid to solid. Each epoxy resin is extraordinary. For best results, the resin should be blended completely in the right proportions.

What are the Different Types of Resin?

There are three main types of resins utilized today: Epoxy, Vinyl ester, and Polyester. These are used in making Carbon Fiber, Fiberglass, and Aramid (Kevlar). Every resin has distinctive attributes and related expenses. All resins have different characteristics – you may look into the items that you will be using and read the manufacturer’s safety precautions and instructions for the correct proportions in mixing hardener and resin.

Epoxy Resin

Epoxy resin is the most expensive among the three types. It is stable in room temperature and reactive when mixed with other chemicals. When combined with a hardener, it becomes the strongest adhesive. Make sure to use an all-weather hardener in applications exposed to water and volatile temperature. Epoxy resin binds well with Carbon Fiber, Fiberglass, and Aramid (Kevlar).

Vinyl Ester Resins

Vinyl ester resins are somewhat similar with epoxy and polyester. It has a flexible characteristic in terms of resilience and elasticity. It can withstand impact and has excellent resistance to other materials such as water, but less resistant to acids. Its ability to bind with other components depend on the size and finish applied on the component fiber. Over time, vinyl ester resin is likely prone to chalking. Chalking is the UV degradation of the resin, releasing the binder’s hold on the pigment, resulting to a powdery surface. This could be avoided by using an additive in the mixture or by applying a 100% acrylic latex topcoat on the surface.

Polyester Resins

Polyester resin is the most commonly used and cheapest among the three. Polyester and vinyl ester can be thinned by combining it with other chemicals such as styrene. The thinning reduces its strength but makes spraying or brushing easier. Polyester is fragile and has low resistance to wear – making it suitable for low-stress applications.

Working with Epoxy Resin

Preparation: Work in a well-ventilated area – you may use a cooler to lower the temperature, or use a warm source to make it higher. Use a tent to make a makeshift workshop if you’re working outdoors. Avoid using propane or diesel-based warmers – this makes dampness likely to develop, making amine become flushed and affect your resin. Use plastic tools such as stirrers and spreaders. Resin is easier to clean on plastic. Cover your work area with wax paper – this is because resin does not stick to wax paper. For safety purposes, wear rubber gloves and eye protection.

Mixing: Work with caution – make sure that you are wearing protective gear before working. Ensure that your resin and hardener are totally mixed and at the right proportion. You may use a plastic mixing container when measuring your resin. Keep in mind that after mixing, you have about 45 minutes before your mixture hardens or cures.

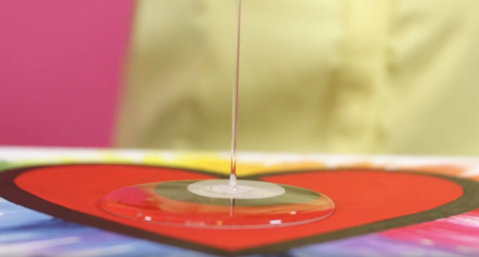

Pouring: You may pour a mixture in a cup to see if it’s cured. When applying the mixture, pour the resin little by little. Use a spreader to guide the resin where you want it to go. In case bubbles appear after pouring, you may use a blowtorch to eliminate these.

Disposal: Follow the manufacturer’s guide for disposing the materials. Wipe your tools with rubbing alcohol and cloth or hand wash and hot water. In case your skin comes in contact with resin, clean it promptly with hand soap and hot water, or use a Resin Removing Cream.

Epoxy resin works well with different materials in making furniture. The exceptional beauty of our Epoxy Resin Coffee Table will bring rustic elegance to your home. If you have any ideas in mind, Chicago Fabrications would love to work with you in designing your own epoxy resin furniture. Call us today at 312-637-1923 or stop in and see us. You can also visit our online store to see the other furniture that we offer.

Subscribe to our newsletter and be the first to get exclusive offers and the best deals!